In industrial manufacturing, research laboratories, and medical facilities, the storage of flammable liquids is not just a matter of organization—it is a critical safety requirement. Among the various sizes available, the H1650mm single door flammable cabinet has emerged as a preferred choice for facilities needing a high-capacity, space-saving solution.

This guide explores the technical specifications, security features, and international standards that make these cabinets an essential investment for your workplace.

1. Understanding the Dimensions: Why H1650mm Matters

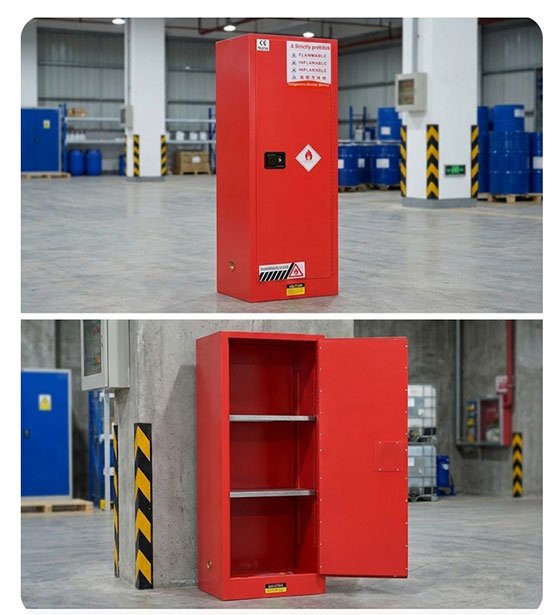

The specific dimensions of this model—Height 1650mm, Width 590mm, and Depth 460mm—offer a unique vertical storage profile. Unlike wider 45-gallon or 60-gallon cabinets, this slim design allows it to be placed in narrow aisles or beside workstations where floor space is at a premium.

With a 22-gallon capacity, it provides ample space for a significant volume of chemical containers while maintaining a small footprint.

H1650mm Single Door Flammable Cabinets Technical Specifications At-A-Glance

| Feature | Specification |

| Height | 1650 mm |

| Width | 590 mm |

| Depth | 460 mm |

| Capacity | 22 Gallons |

| Shelving | 2 Laminate pieces |

| Door Type | Single door with double lock configuration |

2. Key Structural Features for Maximum Protection

A high-quality flammable cabinet is more than just a steel box. It is an engineered safety system designed to withstand extreme heat and prevent the ignition of internal vapors.

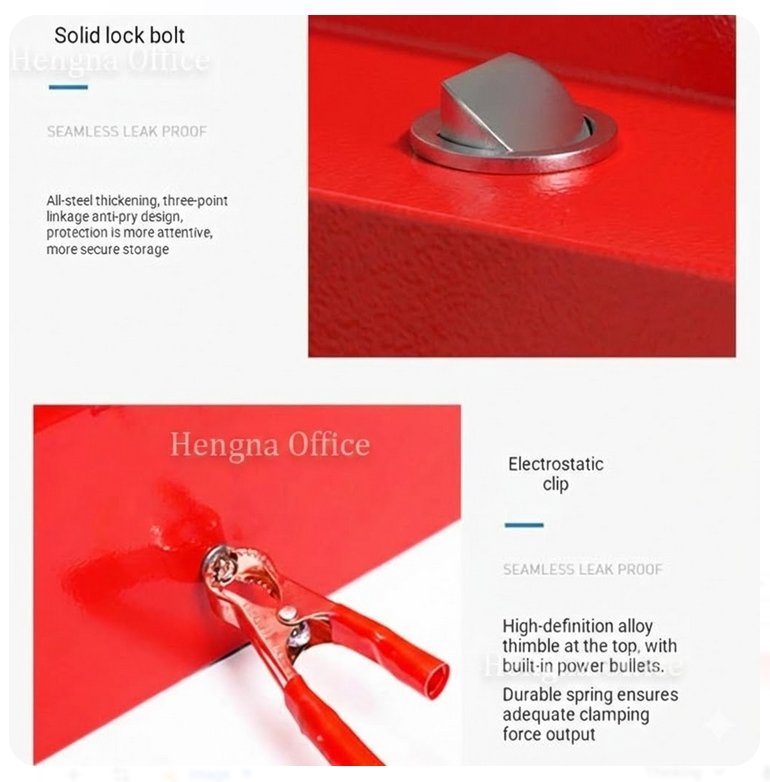

Three-Point Linkage and Thickened Locking Bolts

Security is paramount when storing hazardous materials. These cabinets utilize a three-point linkage system combined with thickened locking bolts.

- Benefit: This ensures the door is secured at the top, middle, and bottom simultaneously, providing a tighter seal and better resistance to prying or warping during a fire.

- User Experience: The recessed handle with a key ensures that the lock does not protrude, preventing it from hooking onto the clothing of passersby in high-traffic areas.

Uninterrupted Piano Hinges

One often overlooked feature is the hinge system. This model features uninterrupted piano hinges (also known as continuous hinges).

- Stability: Unlike standard butt hinges, the continuous hinge supports the entire length of the door, ensuring it does not slide or deform over years of heavy use.

- Smooth Operation: This design allows the cabinet door to switch freely and close with precision, which is vital for maintaining the fire-rated seal.

3. Safety Standards and Certifications

When purchasing a cabinet for industrial use, you must ensure it meets recognized international safety standards. Compliance protects your facility from both fire hazards and legal liabilities.

- CE & RoHS Certification: These models often carry CE and RoHS markings, indicating they meet European health, safety, and environmental protection standards.

- OSHA and NFPA Compliance: In many regions, cabinets must adhere to OSHA 29 CFR 1910.106 and NFPA Code 30. These standards require specific double-wall construction (usually 18-gauge steel with a 1.5-inch air gap) and a 2-inch leak-proof sump at the bottom to contain spills.

- Warning Labels: The cabinets are equipped with high-visibility, reflective warning labels such as “FLAMMABLE,” “INFLAMABLE,” and “Dangerous Goods Safety”. These are crucial for alerting emergency responders during a fire.

4. Selecting the Right Color for Your Chemicals

While the H1650mm model comes in various colors, the color isn’t just for aesthetics. International safety protocols use color-coding to identify the types of liquids stored inside:

- Yellow: The most common color, used for Flammable Liquids like fuels, solvents, and alcohols.

- Red: Reserved for Combustible Liquids, such as paints, inks, and other oil-based products.

- Blue: Typically used for Corrosive Liquids like acids and bases. Note that corrosive cabinets often include polyethylene shelf liners to prevent rust.

5. Storage Efficiency: Laminates and Shelving

The H1650mm model typically includes two laminate pieces (shelves).

- Adjustability: In professional models, these galvanized steel shelves are adjustable, allowing you to customize the internal space for different bottle sizes.

- Spill Direction: High-end shelves are designed to “trough” or tilt slightly toward the back, directing any leaks into the leak-proof sump at the base for safe containment.

6. Installation and Maintenance Tips

To ensure your 22-gallon explosion-proof cabinet performs as intended, follow these best practices:

- Grounding: Always use the built-in grounding lug to prevent the buildup of static electricity, which could ignite flammable vapors during liquid transfer.

- Ventilation: If your local fire code requires it, keep the vent bungs in place unless you are connecting the cabinet to an external exhaust system.

- Leveling: Ensure the cabinet is level. A tilted cabinet may prevent the door from sealing correctly, compromising its fire-resistance rating.

- Do Not Overload: Never exceed the 22-gallon capacity. Overloading can interfere with the self-closing mechanism or the structural integrity of the shelving.

H1650mm Single Door Flammable Cabinet is a proactive step toward a safer industrial environment. Its slim profile, combined with robust features like uninterrupted piano hinges and a three-point linkage lock, makes it a reliable choice for laboratories and manufacturing plants alike.

By adhering to the H1650W590D460mm specifications and ensuring CE/RoHS compliance, you provide your team with the highest level of protection against chemical fires and hazardous spills.

Comparison of Popular Flammable Cabinet Sizes

| Model Capacity | Height (mm) | Best Use Case |

| 12 Gallon | ~890 mm | Under-counter or benchtop storage. |

| 22 Gallon | 1650 mm | Slim, vertical storage for narrow spaces. |

| 30 Gallon | ~1120 mm | Standard waist-high workstation storage. |

| 45 Gallon | ~1650 mm | High-volume storage for large drum-style facilities. |