In the high-stakes environment of a manufacturing plant, safety isn’t just a priority—it’s the foundation of operational continuity. Among the various hazards present on the factory floor, the improper storage of flammable liquids and hazardous chemicals is one of the most significant risks.

Industrial explosion-proof cabinets, often referred to as flammable safety cabinets, are specialized storage solutions designed to isolate hazardous materials from potential ignition sources. Whether you are handling 22 gallons of solvent or bulk industrial chemicals, using the right storage equipment is critical.

In this comprehensive guide, we explore the top five benefits of integrating industrial explosion-proof cabinets into your manufacturing facility.

1. Enhanced Fire Prevention and Heat Isolation

The primary function of an explosion-proof cabinet is to provide a heat-resistant barrier. In the event of a fire in the facility, these cabinets are engineered to keep the internal temperature low enough to prevent the stored chemicals from reaching their auto-ignition point for a specific window of time (usually 10 to 30 minutes).

How it works:

- Double-Wall Construction: High-quality cabinets feature a 1.5-inch (38mm) insulating air gap between two layers of 18-gauge steel.

- Spill-Containment Sills: The bottom of the cabinet usually features a leak-proof sump to catch accidental spills, preventing flammable liquids from spreading across the floor and fueling a fire.

- Flame Arrestor Vents: Dual vents with built-in flame arrestors allow for ventilation while preventing external flames from entering the cabinet.

By containing the fire, these cabinets provide crucial time for employees to evacuate and for emergency services to respond, potentially saving the entire plant from catastrophic destruction.

2. Guaranteed Regulatory Compliance (OSHA & NFPA)

For manufacturing plants, non-compliance with safety regulations can lead to heavy fines, legal liabilities, and even forced shutdowns. In the United States and many international markets, the storage of flammable liquids is strictly governed by OSHA 1910.106 and NFPA 30 (National Fire Protection Association).

Why Compliance Matters:

- Avoid Fines: Safety inspectors look for approved storage methods first. An explosion-proof cabinet with CE or RoHS certification demonstrates a commitment to safety standards.

- Insurance Eligibility: Many industrial insurance providers require the use of FM-approved or UL-listed safety cabinets. Using these cabinets can often lead to lower insurance premiums.

- Global Standards: For plants operating internationally, using cabinets that meet European EN 14470-1 or American NFPA standards ensures a uniform safety protocol across all locations.

3. Improved Organization and Operational Efficiency

A cluttered workspace is a dangerous workspace. Industrial safety cabinets help organize hazardous materials, making them easily accessible yet safely tucked away.

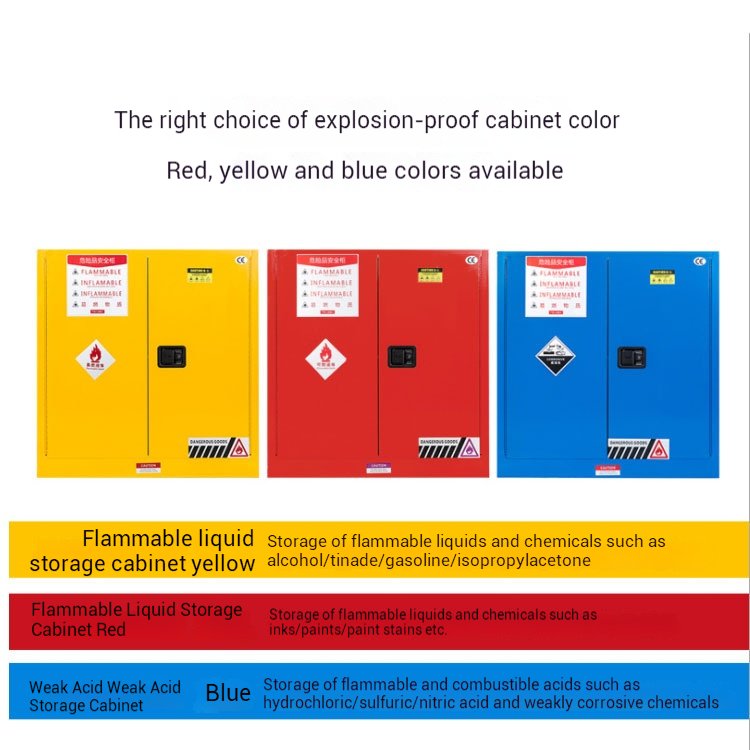

The Power of Color-Coding:

Standardized colors allow workers to identify the contents of a cabinet from a distance, reducing the risk of mixing incompatible chemicals:

- Yellow: Flammable liquids (e.g., fuels, solvents).

- Red: Combustible liquids (e.g., paints, inks).

- Blue: Corrosive liquids (e.g., acids, bases).

- Green: Pesticides or toxic chemicals.

Industrial Explosion-Proof Cabinets for Chemical Storage Efficiency Comparison Table:

| Feature | Standard Shelving | Explosion-Proof Cabinet |

| Safety Level | Low (Exposed to ignition) | High (Heat-isolated) |

| Spill Control | None | Integrated Leak-proof Sump |

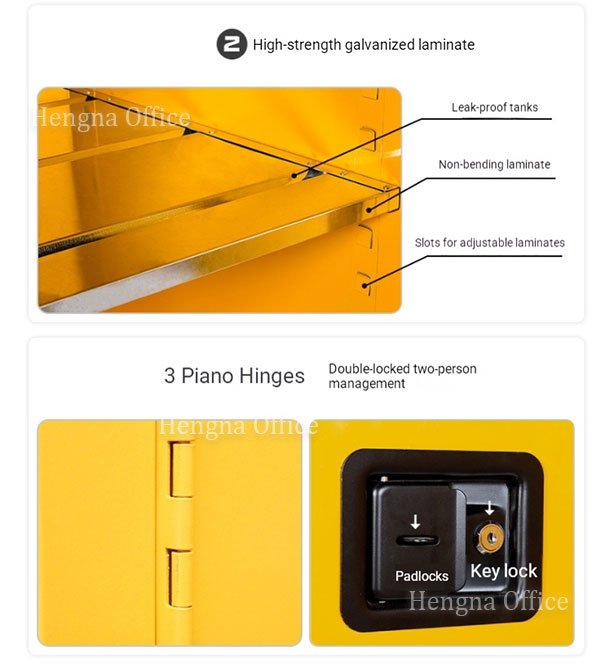

| Access Control | Open access | Double-lock security |

| Labeling | Manual/Often missing | Standardized warning labels |

| Compliance | Non-compliant | OSHA/NFPA Compliant |

4. Protection of Valuable Assets and Personnel

The human cost of a chemical fire is immeasurable, but the financial cost is also staggering. Manufacturing plants house expensive machinery, raw materials, and finished goods.

- Protecting Equipment: A small chemical fire can release corrosive fumes that damage precision machinery. Explosion-proof cabinets contain these fumes and localized fires.

- Employee Peace of Mind: Providing a safe work environment boosts employee morale and retention. When workers know that hazardous materials are stored in high-quality, double-locked cabinets, they can focus on production without fear.

- Security: Most explosion-proof cabinets feature a three-point locking system. This prevents unauthorized access to dangerous chemicals, reducing the risk of theft or accidental misuse.

5. Optimized Space Utilization

Many manufacturing plants struggle with limited floor space. High-quality explosion-proof cabinets, such as the H1650W590D460mm (22-gallon) model, are designed with a slim footprint to fit into tight spaces near workstations.

Point-of-Use Storage:

Instead of forcing workers to travel across a large facility to a centralized chemical warehouse—which increases the risk of spills during transport—these cabinets allow for “point-of-use” storage. You can safely store the chemicals needed for daily operations right where they are used, significantly reducing handling risks and increasing productivity.

Choosing the Right Cabinet: What to Look For

When purchasing an industrial explosion-proof cabinet, consider the following specifications to ensure you are getting the best protection:

- Capacity: Choose a size (e.g., 22 gallons, 45 gallons) that matches your daily volume.

- Adjustable Shelving: Look for galvanized steel shelves that can be adjusted to accommodate different bottle sizes and are designed to direct spills to the back of the cabinet.

- Grounding Lug: Essential for preventing static electricity buildup, which is a common ignition source for flammable vapors.

- Clear Labeling: Ensure the cabinet has reflective, multilingual warning signs (e.g., “Flammable – Keep Fire Away”).

Investing in industrial explosion-proof cabinets is not just about checking a box for a safety audit; it’s about building a resilient manufacturing environment. From the robust double-wall steel construction to the organized color-coding systems, these cabinets offer a multi-layered defense against one of the industry’s most volatile risks.

By prioritizing fire prevention, regulatory compliance, and operational efficiency, manufacturing plants can protect their most valuable assets—their people and their property.

Are you ready to upgrade your facility’s safety? Contact our experts today to find the perfect chemical storage solution for your manufacturing needs.