Safety can’t wait in places where missions are really important. The White Double Cylinder Gas Cabinet is the safest way to store gas. It comes with the Second-Generation (2nd Gen) Smart Alarm System, which is a big step forward in finding and fixing leaks quickly.

This cabinet is made just for places that work with flammable gases that are under pressure, such hydrogen, methane, and propane. It turns passive storage into an active safety barrier, making sure that rules are followed, protecting people, and keeping precious things secure.

Laboratory Safety Double Cylinder Gas Cabinet Key Features and Technical Highlights:

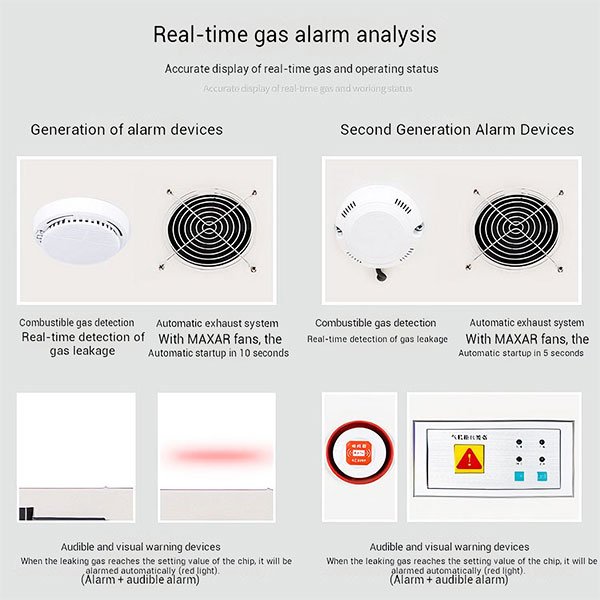

1. Intelligent Real-Time Gas Monitoring and Analysis

- Precision Detection: High-sensitivity combustible gas sensors continuously monitor gas concentration inside the cabinet, detecting leaks instantly.

- Clear Status Display: An intuitive screen provides real-time data on gas levels and system status, enabling operators to assess safety conditions at a glance.

2. Rapid-Response Automatic Ventilation

- Critical Advantage: The 2nd Gen system slashes the ventilation activation time from 10 seconds (1st Gen) to just 5 seconds.

- MAXAR High-Performance Fan: Upon detecting a leak, the system triggers the MAXAR fan within 5 seconds, forcefully expelling accumulated flammable gases and preventing concentrations from reaching explosive limits. This dramatic reduction in response time significantly boosts safety margins.

3. Multi-Stage Audible and Visual Alarms

- Red Flashing Strobe: A bright red strobe light captures immediate visual attention, even in noisy or poorly lit environments.

- 85 dB Sound Alarm: A loud alarm cuts through background noise, alerting all personnel in the vicinity to take swift action.

4. Comparison: 1st vs. 2nd Generation Alarm Systems

| Feature | 1st Generation | 2nd Generation |

|---|---|---|

| Gas Detection | Yes | Yes |

| Automatic Ventilation | Yes (MAXAR fan) | Yes (MAXAR fan) |

| Audible/Visual Alarm | Yes | Yes |

| Ventilation Response Time | ≤10 seconds | ≤5 seconds |

Technical Specifications

- Dimensions: 1900mm (H) × 450mm (W) × 900mm (D)

- Alarm System: 2nd Generation Smart Audio-Visual Alarm

- Ventilation: MAXAR high-performance fan, response time ≤5 seconds

- Alarm Methods: Red flashing strobe + ≥85 dB sound

- Monitored Gases: Combustible gases (e.g., hydrogen, methane, propane)

- Cabinet Material: Cold-rolled steel with white epoxy coating

- Capacity: Standard double gas cylinder storage

Versatile Applications

This gas cabinet is ideal for a wide range of sectors, including:

- Research & Education: University labs, research institutes, testing centers.

- Healthcare: Hospital central oxygen rooms, clinical labs, surgical gas supply stations.

- Industrial: Petrochemical plants, semiconductor manufacturing, pharmaceutical factories, gas stations.

- High-Tech Fields: Cleanrooms for new energy battery R&D, materials science facilities.

Safety, Compliance, and Quality Assurance

Designed and manufactured in accordance with international safety standards (including OSHA and NFPA guidelines), this cabinet embodies best practices in industrial safety. Its proactive safety approach helps organizations build a culture of excellence and responsibility.

Why Choose Our 2nd Gen Gas Cabinet? (Value Proposition Summary)

- Proactive Safety, Not Passive Storage: The 2nd Gen system shifts from passive storage to active monitoring and intervention, stopping incidents before they escalate.

- Ultra-Fast Response: The Golden 5 Seconds: Our industry-leading $\le 5\text{-second}$ exhaust startup time provides the most critical safety window available for emergency accident handling.

- Reliable Performance, Core Excellence: Utilizes the validated MAXAR fan to ensure consistent, high-efficiency ventilation and long-term system stability.

- Human-Centric Design, Clear Visibility: Clear status displays and unmissable alarm alerts significantly reduce the risk of human error.

- Durable and Professional: High-quality materials, professional white finish, and robust craftsmanship ensure longevity and elevate the aesthetic of your working environment.

Secure your facility with the most advanced gas safety technology available. Contact our B2B sales team for detailed pricing and customized compliance documentation.

❓ Frequently Asked Questions (FAQs)

This section addresses common questions about the safety, operation, and compliance of the 2nd Gen Double Cylinder Gas Cabinet.

Q1: What is the primary advantage of the 2nd Gen Smart Alarm System over the 1st Gen?

The core advantage is the response time of the automatic exhaust system. The 1st Gen system initiates ventilation in $\le 10\text{ seconds}$, whereas the 2nd Gen system reduces this critical response time to $\le 5\text{ seconds}$. This 50% reduction in activation time provides an exponentially larger safety margin, ensuring that accumulated flammable gases are evacuated before they reach their Lower Explosive Limit (LEL).

Q2: Which types of gases can this cabinet safely monitor and store?

This cabinet is specifically equipped with a high-sensitivity sensor designed to monitor flammable/combustible gases. This includes, but is not limited to:

- Hydrogen ($H_2$)

- Methane ($CH_4$)

- Propane ($C_3H_8$)

- Acetylene ($C_2H_2$)

The cabinet is designed for the safe, regulated storage of standard high-pressure gas cylinders used in industrial and laboratory settings.

Q3: What happens when the gas leak alarm is triggered?

When the integrated sensor detects a gas concentration exceeding the preset threshold, three actions occur simultaneously within $\le 5\text{ seconds}$:

- The $\ge 85\text{ dB}$ audible alarm sounds to alert personnel.

- The red flashing light activates for visual warning.

- The MAXAR high-performance exhaust fan automatically starts, rapidly extracting the gas from the cabinet to the external ventilation system.

Q4: Are the dimensions customizable, and is the cabinet compliant with regulations?

The standard dimensions are $1900\text{mm} (H) \times 450\text{mm} (W) \times 900\text{mm} (D)$ and are optimized for standard laboratory spacing. We offer options for custom specifications upon request to accommodate unique facility requirements.

Regarding compliance, the cabinet is built using materials and engineering practices that adhere to major international and domestic Safety and Fire Codes for the storage of compressed and hazardous gases.

Q5: How does the adjustable fixing rack (chain) work?

The cabinet features a heavy-duty, adjustable steel restraint system (chain) inside the storage compartment. This system allows operators to securely fasten different sizes and diameters of gas cylinders, ensuring they remain upright and stable, preventing accidental tipping, which is a major cause of regulator damage and leaks.

Q6: How does the power supply and ventilation connection work for the alarm system?

The cabinet’s alarm system requires a standard electrical power supply for continuous monitoring and to operate the MAXAR exhaust fan. The fan outlet is designed to be easily connected to your facility’s dedicated external ventilation system or exhaust ductwork (typically via a Ø100mm port, though specific port sizes can be confirmed upon order). This ensures that any extracted gas is safely routed out of the workspace.